Mike Gottke, Stagehand & Frontline Hero

This week we're sharing the story of a group of union members who lost their jobs at the start of the coronavirus crisis and immediately threw their hands and hearts into a volunteer effort to protect the lives of frontline workers by making plexiglass face shields. Mike Gottke, an I.A.T.S.E. Local 11 stagehand shares the story of the Charlestown Face Shield Project with us as part of the Greater Boston Labor Council's #FrontlineHeroes series. Our series profiles the work of union members and everyday heroes who are working on the frontlines during the global pandemic. Stories are updated weekly. To read about other Frontline Heroes, click here: https://gblc.us/tag/frontline-heroes.

The Charlestown Face Shield project started as a small operation by Chad Bennett of Dark Monk, a local manufacturer of fire entertainment equipment. Chad converted his company to design and produce much needed face shields for hospitals as soon as the coronavirus hit.

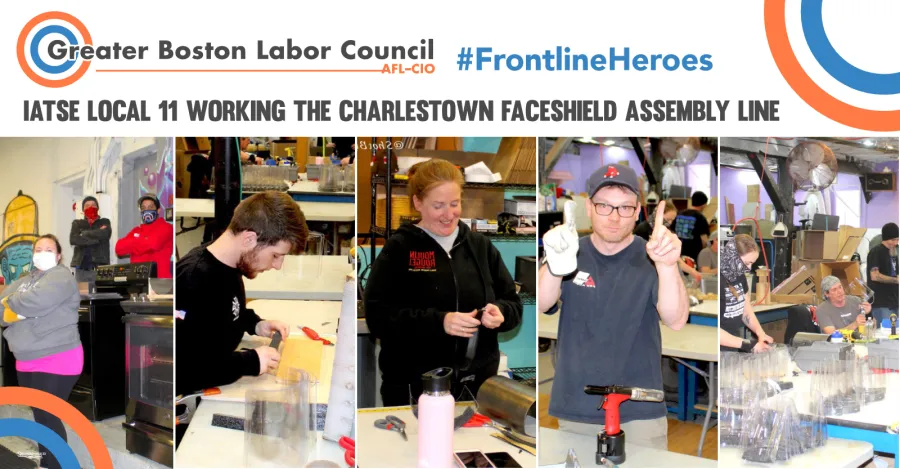

Mike Gottke, a production stagehand at Boston Lyric Opera, and other fellow I.A.T.S.E Local 11 union members volunteered to make face shields for frontline workers about 6-8 hours a day for six weeks. Mike was laid off as soon as the Covid-19 crisis hit, but jumped right into the volunteer project, using his 30 years of production experience to help work out some kinks in the face shield assembly line and increase production dramatically. "We created a smoother and faster line which could produce up to 2,100 masks a day, up from the 70 per day the project had been producing - that's what stagehands do," said Mike.

Every day for the last six weeks, Mike has overseen the assembly line and put headband straps on the shields, as the last step in assembly. There were nine workers on the line who formed the shields from raw plexiglass and then applied foam padding, silicone and a headband and an additional 4 stagehands running ovens daily at a food truck kitchen in Everett. Volunteer workers then counted and shipped the masks at no cost to hospitals, firehouses and even the National Guard on the frontlines.

Mike worked on this project to help "protect our doctors, nurses, healthcare workers and first responders." He added, "if we can give them another layer of protection so that they can do their jobs safely, then we can all get back to a working economy." The Charlestown project is one of the only in the nation to make their shields at such a high volume and at absolutely no cost to workers or facilities in need.

With the global pandemic changing everyone's lives, these union members have found a way to give back. Mike values his membership in I.A.T.S.E. 11, "it's a good union with good people and we're always looking for ways we can give back to our communities."

The team finished up the project this week by reaching their production goal, with a grand total of 30,131 shields made in just under 6 weeks’ time. Shields were delivered to over 100 facilities from Boston to Cape Cod, New York, New Jersey and even a shipment to Navajo Nation for the front line workers in Arizona and New Mexico.

Mike emphasized that they wouldn’t have been able to provide this vital resource to frontline workers without generous donations from everyday people. Even though the production line has wrapped up, the Charlestown Face Shield Project is still $12,000 shy of covering their raw material costs. Please donate if you are able, all donations go directly to covering face shield costs: https://www.gofundme.com/f/face-shields-for-local-boston-hospitals